![[field:title/]](/uploads/allimg/c211020/1634EOSO210-151134.jpg)

Stone Impact Crusher

CE Certificated Phosphate Stone Impact Crusher Product Description Introduction to the Stone Impact Crusher Stone Impact Crusher can be widely used in water, electricity, highway to make suitable sand and stone. Three-cavity crush area which is applied to crush high quality stone aggregate...

CE Certificated Phosphate Stone Impact Crusher

Product Description

Introduction to the Stone Impact Crusher

Stone Impact Crusher can be widely used in water, electricity, highway to make suitable sand and stone. Three-cavity crush area which is applied to crush high quality stone aggregate material with cubical shape, rotor connected without key awl, high chrome hammer, unique impact liner, deal with hard material, high efficiency and save energy, cubic shape of product, adjustable output size. It has a high ratio of reduction, direct control of product gradation and excellent cubical product shape. Our impact crusher is available in different models with capacity from 10-500TPH.

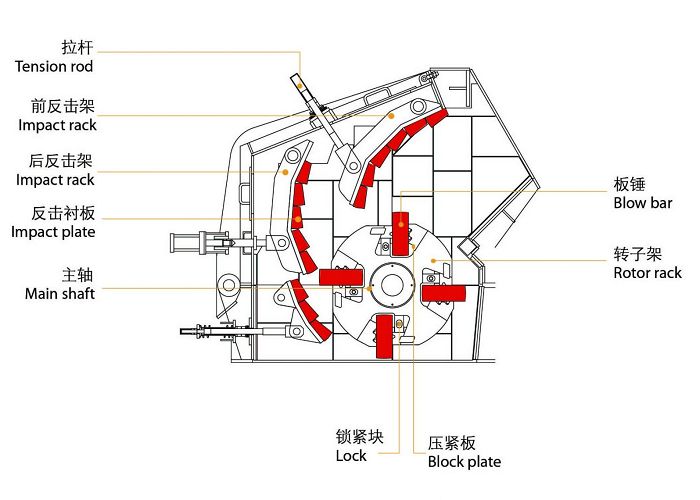

Stone Impact Crusher’s Working principle

When the impact crusher works, the motor drives the rotor rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. The materials from large to small all to be crushed at the impact chamber repeatedly. The process won't stop till the material are crushed to the required size and then discharged from outlet.

Stone Impact Crusher Features and Benefits:

1. Even crushing function of multi-cavities which is suitable to crush Hard material.

2. Reasonable design of leveling plate making the finished material finer and cubic-shaped without internal cracks.

3. Hydraulic start-up which is convenient for maintenance and replacement of wearing parts.

4. New anti-abrasive material which prolong service life of impact hammer, impact plate and liner.

5. High reduction ratio and crushing efficiency.

6. No-board connection; The blow bar with high chrome (high chromed blow bar).

7. Impact plate with a special shape.

8. Crushed product with cubical shape.

9. Easy maintenance and reliable operation.

Stone Impact Crusher Main Technical Parameters:

Model | Specification (mm) | Feeding size(mm) | Max feed size(mm) | Capacity (t/h) | Motor power(kw) | Weight(kg) |

PF-0607 | 644*740 | 320*770 | 100 | 10-20 | 30 | 10216 |

PF-0807 | 850*700 | 400*730 | 300 | 15-30 | 30-45 | 11138 |

PF-1008 | 1000*800 | 400*830 | 300 | 30-50 | 37-55 | 12206 |

PF-1010 | 1010*1050 | 400*1080 | 350 | 50-80 | 55-75 | 13138 |

PF-1210 | 1250*1050 | 400*1080 | 350 | 70-120 | 110-132 | 15200 |

PF-1212 | 1250*1250 | 400*1300 | 350 | 100-150 | 132-160 | 17025 |

PF-1214 | 1250*1400 | 400*1430 | 400 | 130-180 | 160-200 | 19015 |

PF-1315 | 1320*1500 | 860*1520 | 500 | 160-250 | 180-260 | 24600 |

PF-1320 | 1320*2000 | 860*2030 | 500 | 300-350 | 300-375 | 29800 |

PF-1520 | 1520*2000 | 980*2980 | 700 | 400-500 | 400-480 | 38600 |

Packaging & Shipping

Delivery for Stationary crushing plant

Export standard container 20GP OR 40GP, 40HQ the spare parts in wooden case.

Our Services

Service:

1) Pre-sale service:Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export.

3) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

Service supervision

Any dissatisfaction on service attitude, service skills, quality and morality of our technical staff , please feel free to contact us by dialing 24 hours hot line: 0086-15980012906.